When to Call for Professional Packaging Machine Repair in Your Facility

Wiki Article

Just How to Optimize Efficiency With Expert Product Packaging Device Fixing Provider

Understanding the critical duty of product packaging equipments, organizations need to recognize the indicators that indicate a demand for repair service and the advantages of involving specialist solutions. Selecting the appropriate repair work service and implementing effective preventative upkeep strategies stays important.Comprehending Packaging Equipment Significance

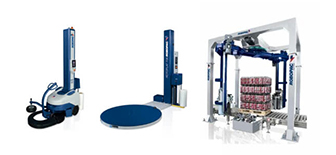

Why is the product packaging machine considered a crucial aspect in modern manufacturing? Packaging devices play an essential duty in enhancing operational efficiency, product conservation, and consumer charm. In an open market, the ability to bundle items quickly and effectively straight influences a company's profits. High-speed product packaging equipments can enhance manufacturing processes, minimizing labor expenses and lessening human mistake, while maintaining high throughput rates.Moreover, advanced product packaging equipments are made to fit numerous product packaging types, such as bottles, pouches, and boxes. This adaptability permits manufacturers to adjust to transforming market demands and consumer preferences without considerable downtime. Additionally, effective product packaging makes sure item honesty throughout transportation and storage space, minimizing waste and spoilage and ultimately adding to sustainability initiatives.

Additionally, product packaging makers integrate flawlessly with various other making systems, facilitating a smooth process from production to distribution. This interconnectedness not only enhances productivity however likewise offers important information analytics for continual improvement. In summary, the relevance of product packaging machines in modern-day production can not be overstated; they are vital for preserving competitive benefit and accomplishing operational quality in today's busy organization environment.

Indications Your Equipment Demands Repair

Identifying the indications that your packaging device needs repair service is vital for keeping production performance and minimizing downtime. Routine surveillance of equipment efficiency can help detect concerns before they rise into considerable problems.Among the very first indicators is an unusual increase in sound levels during operation. If the machine starts to generate grinding or clattering noises, it may show mechanical wear or imbalance. Additionally, irregular item outcome, such as uneven product packaging or mislabeling, can recommend that the maker's calibration is off, calling for immediate interest.

Another important indicator is regular mistake messages or unforeseen shutdowns. These interruptions can drastically impact output and signal hidden electrical or software concerns. Moreover, if you observe a decrease in rate or effectiveness, with the device taking longer to complete jobs, it might be a forerunner to a lot more severe mechanical failures.

Last but not least, physical signs such as fraying belts, leaking fluids, or excessive resonance needs to not be ignored, as they typically indicate parts that are on the brink of failing - packaging machine repair. Promptly addressing these signs and symptoms can stop pricey fixings and make certain ideal operational efficiency

Advantages of Specialist Repair Service Solutions

In addition, professional repair work services typically have accessibility to innovative analysis tools and innovations that promote an extensive evaluation of devices condition. This not only help in immediate repairs but additionally enables anticipating upkeep, avoiding future failures and expanding the life-span of equipment.

In addition, making use of professional services can lead to improved safety criteria, as skilled service technicians are skilled in market policies and best techniques. This minimizes the risk of accidents caused by inappropriate handling or maintenance. Ultimately, the financial investment in expert repair service services converts to set you back savings by maximizing maker performance, boosting product quality, and making sure compliance with safety requirements, every one of which add to a more reliable manufacturing environment.

Picking the Right Repair Work Solution

A fixing service that offers 24/7 assistance can avoid minor concerns from intensifying right into expensive manufacturing halts. Look for business that give an in-depth service contract, outlining their service warranties, valuing structures, and parts schedule.

Moreover, examine consumer evaluations and testimonials to assess the reliability and expertise of the company. A reputable business will certainly have a history of satisfied clients, which talks quantities regarding their solution top quality. Finally, guarantee that the professionals are certified and learnt the latest innovations and ideal methods, as this expertise is vital for reliable repairs and maintenance. By click this thoroughly picking a repair service, you can enhance the longevity and performance of your packaging devices.

Preventative Upkeep Approaches

Applying preventative upkeep approaches is crucial for making certain the optimum performance and longevity of packaging devices. Routinely scheduled upkeep not just minimizes the chance of unforeseen break downs but additionally improves general operational efficiency.An aggressive maintenance schedule need to consist of regular evaluations, lubrication of relocating parts, and looking for damage on critical parts. These examinations can recognize prospective issues prior to they escalate right into pricey repair services or downtime. Furthermore, keeping precise records of upkeep activities can assist track machine performance trends and guide future maintenance decisions.

Educating personnel on proper operating treatments is another crucial aspect. Workers need to be informed on recognizing very early indicators of device breakdown, which can facilitate prompt intervention. Additionally, using resonance evaluation and thermal imaging technology can additionally enhance the maintenance method by determining problems that might not show up to the naked eye.

Verdict

In conclusion, taking full advantage of effectiveness with professional packaging equipment fixing services demands an aggressive technique that includes regular upkeep, prompt repair services, and the know-how of proficient specialists. Executing sophisticated diagnostic devices and promoting relationships with reliable repair service solutions add to improved operational efficiency and decreased downtime. By focusing on these strategies, organizations can ensure the long life and efficiency of their product packaging machinery, ultimately causing enhanced performance and versatility in response to progressing production demands.Recognizing the important role of product packaging machines, services discover here should recognize the indications that show a requirement for fixing and the advantages of involving expert solutions.Addressing the indications of wear and breakdown in packaging devices promptly is only component of the formula; leveraging professional repair service solutions can significantly boost operational performance.Picking the best packaging maker repair solution is essential for preserving functional performance and minimizing downtime. By thoroughly choosing a fixing service, you can enhance the longevity and performance of your packaging equipments.

In conclusion, maximizing efficiency with professional packaging device repair service services demands a positive technique that consists of routine maintenance, prompt fixings, and the proficiency of competent specialists.

Report this wiki page